1802

история завода

>15

>10

тыс.

тыс.

тыс.

>10

История «Александровского машиностроительного завода» началась в 1802 году, когда указом № 1455 Уральской берг-коллегии графу В. А. Всеволожскому было поручено строить на реке Лытве «железоделательный завод»

Общая длина изготовленных конвейеров

Выпущенно горно-шахтного оборудования

Общий объем выпуска литейной продукции

основание завода

ед

км

тонн

Сегодня АО «АМЗ» располагает полным производственным циклом — от производства собственного сырья до комплектующих для производимой продукции

Токарная обработка крупногабаритных деталей

Оборудование по нарезке зуба

Продольно-строгальная обработка заготовок

Выплавка марочной стали, чугуна и отливки в формы

Производственные мощности

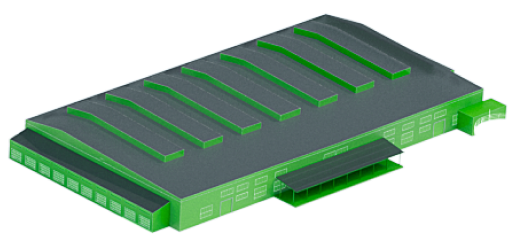

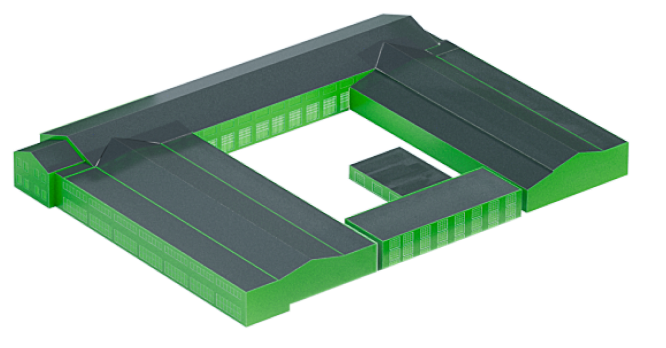

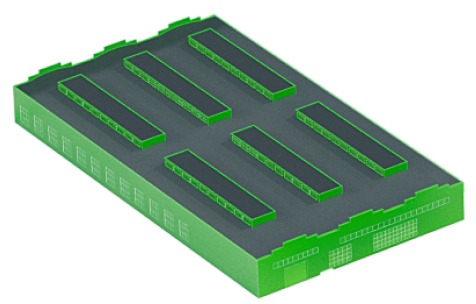

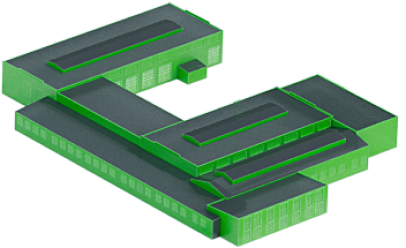

Земельный участок в 90 Га

78,000 м² производственных помещений

7 производственных и 3 вспомогательных цеха

Собственное конструкторское бюро

До 5м в длину, 2м в диаметре

и до 30 тонн веса

и до 30 тонн веса

Диаметром до 3м,

до 10 тонн веса

до 10 тонн веса

До 3.2x8.0 м,

весом до 100 тонн

весом до 100 тонн

От 2 до 2000 кг

Механо-сборочный цех №7

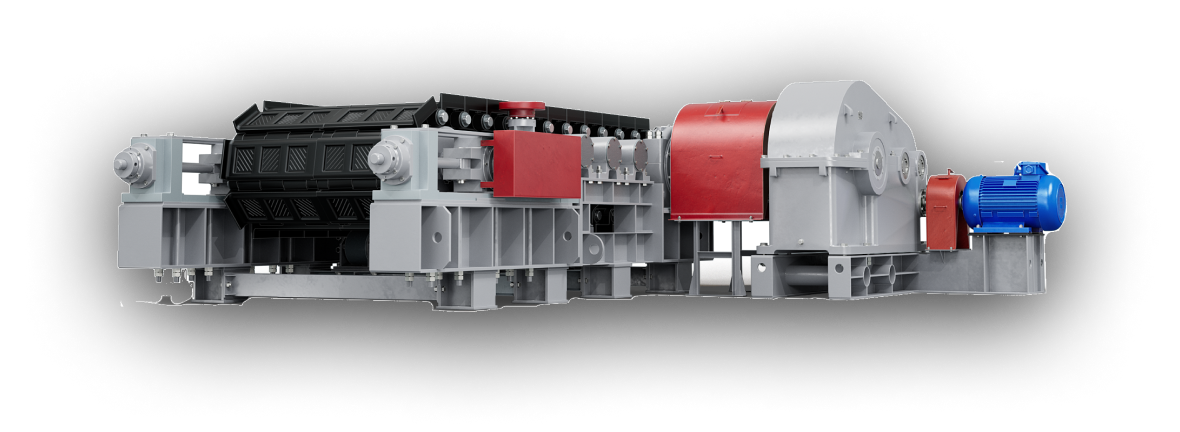

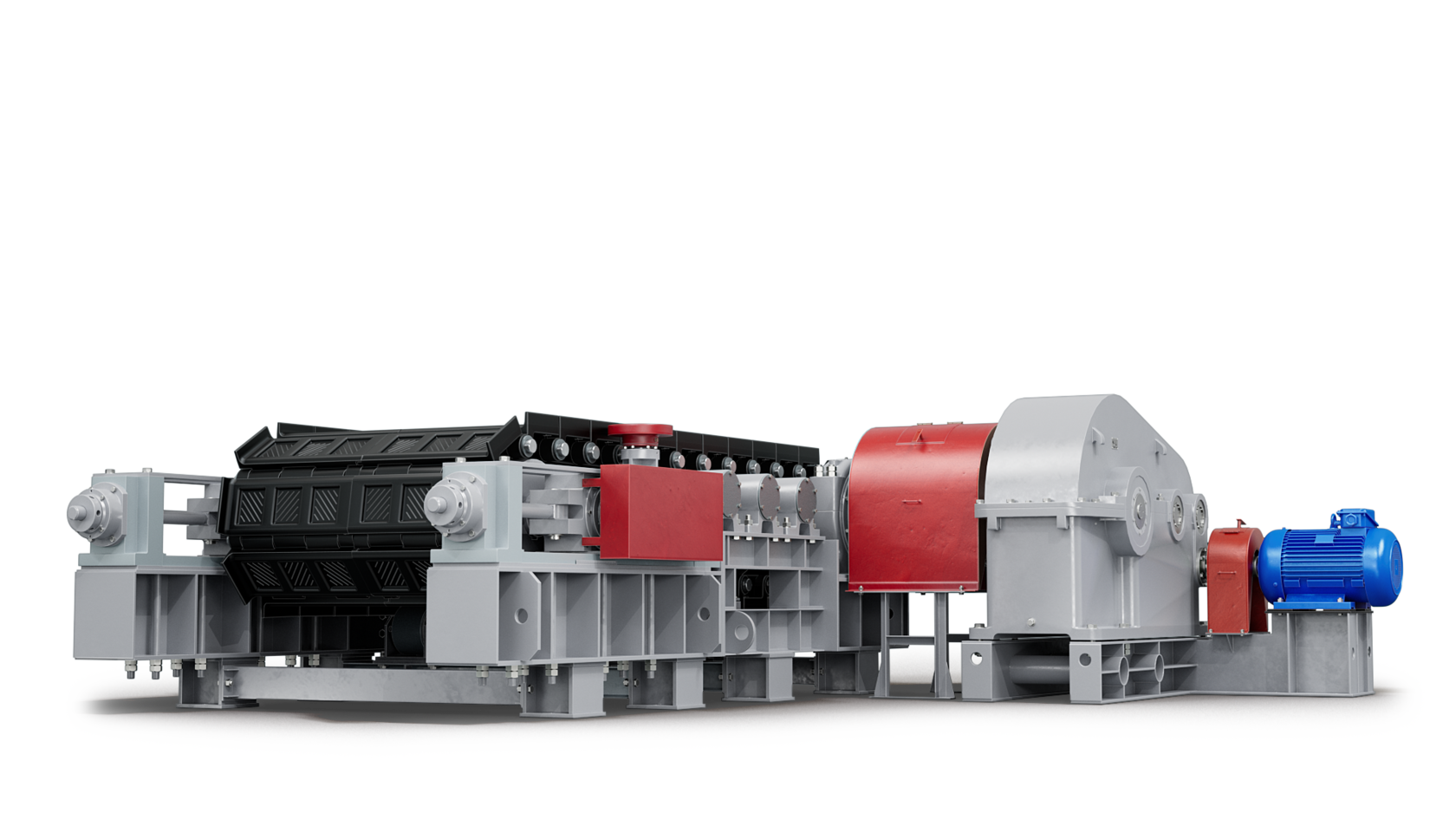

В цехе выполняют механическую обработку, окрашивание и сборку магистральных конвейеров шириной 1200мм и более, электровозы, пластинчатые питатели, вагонетки

В цехе выполняют механическую обработку, окрашивание и сборку магистральных конвейеров шириной 1200мм и более, электровозы, пластинчатые питатели, вагонетки

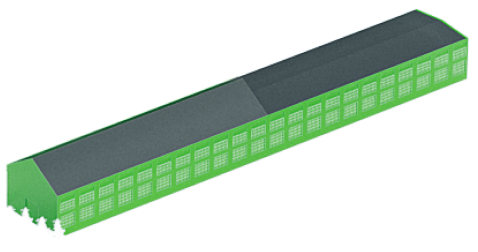

Цех изготовления и сборки роликов №20

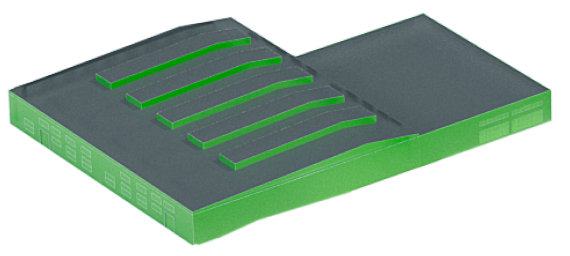

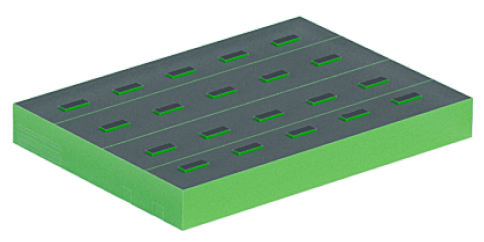

В цехе изготовляют детали и сборку конвейерных роликов: диаметром от 89 до 159мм, длиной от 200 до 2000мм

В цехе изготовляют детали и сборку конвейерных роликов: диаметром от 89 до 159мм, длиной от 200 до 2000мм

Литейный цех №10

В литейном цехе изготавливают отливки массой до 2000 кг, методом литья в песчано-глинистые формы, из стали 30Л,45Л,60Л, 35ХМЛ, 65ГЛ и чугуна СЧ10-СЧ20

В литейном цехе изготавливают отливки массой до 2000 кг, методом литья в песчано-глинистые формы, из стали 30Л,45Л,60Л, 35ХМЛ, 65ГЛ и чугуна СЧ10-СЧ20

Порезочный участок цех №3

Резка профилей на пресс-ножницах: уголки от 32х32х4 до 100х100х12, швеллера № от 8У до 30У, трубы.

Резка профилей на пресс-ножницах: уголки от 32х32х4 до 100х100х12, швеллера № от 8У до 30У, трубы.

Механо-сборочный цех №1

В цехе выполняют механическую обработку (токарную, фрезерную, зубообрабатывающую), изготовление барабанов и редукторов: цилиндрических, коническо-цилиндрических, червячных.

В цехе выполняют механическую обработку (токарную, фрезерную, зубообрабатывающую), изготовление барабанов и редукторов: цилиндрических, коническо-цилиндрических, червячных.

Цех заготовительный, сборки и сварки металлоконструкций №6

Плазменная и газовая резка листового проката, пробивка профиля на различных прессах, гибка, вальцевание обечаек, ручная электродуговая и полуавтоматическая сварка

Плазменная и газовая резка листового проката, пробивка профиля на различных прессах, гибка, вальцевание обечаек, ручная электродуговая и полуавтоматическая сварка

Механо-сборочный цех №5

В цехе выполняют механическую обработку (токарную, сверлильную, фрезерную, строгальную), окрашивание и сборку участковых конвейеров шириной до 1000мм

В цехе выполняют механическую обработку (токарную, сверлильную, фрезерную, строгальную), окрашивание и сборку участковых конвейеров шириной до 1000мм

Кузнечно-прессовое производство цех №8

В кузнечно-прессовом цехе выпускают поковки весом до 700кг, штамповки весом до 15кг, выполняют следующие виды ТО: закалка на воду и масло, отпуск, нормализацию, цементацию, ТВЧ

В кузнечно-прессовом цехе выпускают поковки весом до 700кг, штамповки весом до 15кг, выполняют следующие виды ТО: закалка на воду и масло, отпуск, нормализацию, цементацию, ТВЧ

Инженерный корпус

В настоящее время АО «АМЗ» имеет все необходимые условия для изготовления горно-шахтного оборудования самого высокого, конкурентоспособного качества

Продукция

Продукция АО «АМЗ» неоднократно была удостоена дипломами выставки «Уголь и Майнинг России» и ряда международных наград и не уступает по своим характеристикам зарубежным аналогам

география ПОСТАВОК

Березники

Горно-химическое сырье

Горно-химическое сырье

Нерюнгри

Минеральное сырье

Минеральное сырье

Анадырь

Минеральное сырье

Минеральное сырье

Воркута

Минеральное сырье

Минеральное сырье

Новокузнецк

Минеральное сырье

Черный и легирующий металл

Минеральное сырье

Черный и легирующий металл

Приморский Край, пгт Восток

Черный и легирующий металл

Черный и легирующий металл

Череповец

Черный и легирующий металл, цветной металл

Черный и легирующий металл, цветной металл

Норильск

Цветной металл

Цветной металл

Березовский

Цветной металл

Цветной металл

Соль-Илецк

Горно-химическое сырье

Горно-химическое сырье

Апатиты

Горно-химическое сырье

Горно-химическое сырье

Абаза

Нерудное сырье

Нерудное сырье

Губкин

Нерудное сырье

Нерудное сырье

пос. Вершино-Дарасунский

Драгоценное сырье

Драгоценное сырье

Мирный

Драгоценное сырье

Драгоценное сырье

Актобе, Республика Казахстан

Черный и легирующий металл

Черный и легирующий металл

Темиртау, Республика Казахстан

Черный и легирующий металл

Черный и легирующий металл

Навои, Республика Узбекистан

Цветной металл

Цветной металл

п. Бешбулак, Дехканабадский район, Республика Узбекистан

Горно-химическое сырье

Горно-химическое сырье

Македонска Каменица, Республика Македония

Цветной металл

Цветной металл